The metal casting industry is constantly evolving, driven through the demand for increased precision, enhanced top quality, and reduced defects. In this particular landscape, the pressure casting equipment plays a vital function. on the other hand, for probably the most demanding purposes, a specialized style of casting machine is necessary: the vacuum strain casting equipment. this information explores the one of a kind benefits of these equipment, focusing on how they greatly enhance the accuracy and top quality of metallic casting, especially for important metals like gold and platinum.

Table of contents:

some great benefits of Using Vacuum strain Casting devices for High-excellent final results

How Vacuum Pressure Casting boosts the Accuracy of Gold, Platinum, along with other Metals

Why Vacuum force Casting is important for significant-Precision Industries

some great benefits of Using Vacuum stress Casting equipment for prime-excellent success

Vacuum pressure casting machines give a significant step forward when compared with regular casting procedures. The Main advantage lies from the elimination of air pockets and gas porosity throughout the casting. By performing the casting system below a vacuum, the molten metallic is permitted to move far more freely and totally fill the mould cavity. This ends in denser, more robust castings with less interior defects. In addition, the application of strain through the solidification stage really helps to further consolidate the metallic, minimizing shrinkage and increasing the general quality. This makes vacuum stress casting ideal for developing intricate and complicated layouts exactly where even the smallest imperfections can compromise the features or aesthetic attraction of the ultimate merchandise.

How Vacuum strain Casting improves the precision of Gold, Platinum, as well as other Metals

The large worth and exceptional Houses of valuable metals like gold and platinum necessitate Remarkable casting precision. Vacuum gold casting machine know-how is exclusively made to fulfill these demanding needs. The vacuum natural environment not just stops oxidation of your molten metallic but in addition assures a clean up and constant casting procedure. This is especially significant for gold, which can certainly tarnish or build area defects if subjected to air throughout casting. In addition, the controlled pressure used through solidification encourages uniform grain construction and minimizes the chance of cracking or distortion. This ends in castings that happen to be dimensionally correct, possess excellent surface area finish, and keep the desired mechanical Qualities.

Why Vacuum stress Casting is important for large-Precision Industries

High-precision industries, such as aerospace, health care unit manufacturing, and substantial-conclusion jewelry generation, depend upon vacuum pressure casting to achieve the stringent excellent standards essential for his or her applications. the chance to make castings with restricted tolerances, small defects, and consistent substance Houses is paramount in these sectors. as an example, while in the aerospace business, vacuum pressure cast elements are used in essential engine components wherever dependability and performance are non-negotiable. in the same way, in health-related product manufacturing, vacuum force casting guarantees the biocompatibility and structural integrity of implants. The benefits prolong to jewellery earning likewise, in which intricate layouts and flawless finishes are important for generating high-worth pieces. Ultimately, vacuum pressure casting gives the necessary Regulate and precision to fulfill the demanding Vacuum gold casting machine prerequisites of those industries. As evidenced by merchandise just like the TAKJ-VC-W obtainable at https://taeantech.com/products/takj-vc-w, these machines are especially intended to cater to your precision essential by vacuum stress casting procedures.

In conclusion, vacuum force casting machines are indispensable resources for attaining substantial precision and outstanding top quality in metallic casting. The mixture of vacuum environment and managed pressure gets rid of common casting defects, improves materials Qualities, and ensures dimensional accuracy. For industries demanding the best amounts of efficiency and dependability, buying vacuum stress casting engineering is not only a preference but a requirement. Consider the precise necessities of one's application and discover the varied vacuum stress casting answers accessible to unlock new options in steel casting and elevate the caliber of your last items.

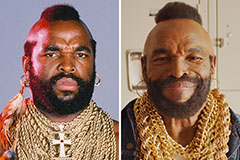

Mr. T Then & Now!

Mr. T Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!